We remain committed to our ambition to become climate neutral within our operations and our fleet and drive competitive advantage through our ability to offer low-carbon solutions to our clients

Road to net-zero

The pace at which we move towards our emission-reduction targets depends on the opportunities and technology available to different parts of the company. It is important to differentiate between areas where we have direct control and significant influence over reductions – such as in our onshore operations where we have adopted numerous measures to progress the switch to clean sources of energy – and where our influence is indirect or reliant on the progress made by third parties. Our largest contribution to greenhouse gas emissions comes from our vessels. To achieve substantial emission reductions within the fleet we are dependent not only on suitable alternatives to fossil fuels, but also their availability and the necessary infrastructure to serve our global maritime operations.

We support the net zero 2050 transition pathway for international shipping set by the International Maritime Organization (IMO) in July 2023. This industry pathway includes a mid-term reduction ambition to reduce carbon intensity by 2030. In line with this pathway, we aim to achieve a 10% reduction in carbon intensity relative to 2023 through several energy efficiency measures and the use of renewable fuels. A carbon intensity ratio, developed in-house, which is in line with the IMO intensity ratio will allow us to monitor progress against our ambition and track the energy efficiency of our vessels. This ratio expresses the emissions relative to the utilized installed power of a vessel.

Commercial offerings

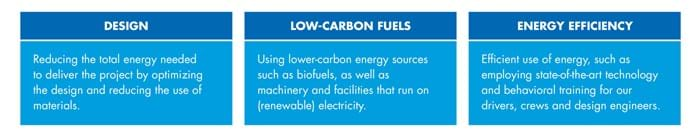

Wherever possible, we encourage our clients to adopt sustainable and low-carbon solutions to help reduce emissions. This is done in two principal ways: through the optimization of project designs to reduce energy, increase circularity and limit the consumption of materials; and by using low-carbon energy sources such as biofuels or (renewable) electricity to power our vessels and dry earthmoving equipment.

Onshore operations

We are investing in low-emission equipment in support of our ambitions for all onshore projects in the Netherlands to become climate neutral by 2030. In line with this ambition, we have put together a detailed investment plan aimed at clean fuel alternatives. We have invested in electric equipment such as excavators and earthmoving trucks, while existing machinery has been converted from traditional fuels to electric. We have also purchased an Energy Storage System that can be deployed to different projects to charge our equipment, thereby retaining charging options – and the necessary flexibility – in-house.

Over the last few years we have taken numerous steps to further reduce the carbon footprint across our offices and warehouses. We have installed solar panels at a number of our premises in the Netherlands and abroad, including our Papendrecht headquarters, which together generate more than three million kilowatt hours of green electricity each year. Our distribution center in Vlaardingen holds an energy label A+++ and is CO2 negative. More recently, we installed a total of 820 panels on the roof of our office in Singapore, which provide for approximately 60% of the building’s total electricity usage.

Our fleet

In recent years we have devised and adopted a range of measures and new technologies to drive down fuel consumption and reduce emissions from our fleet. Meanwhile we collaborate extensively with our industry peers in the development of the expertise and technology necessary for the sector to complete its energy transition.

We are currently enacting our plans to retrofit numerous vessels within our offshore fleet through Energy Storage Systems, or ‘power packs’. These conversions will reduce the vessels’ fuel consumption and associated carbon dioxide and nitrogen oxide emissions by an average of up to 20% during DP operations. The systems also provide a power supply and energy storage facility while the vessels are docked and contribute to quieter and more efficient operations offshore. Other measures to reduce emissions within our fleet include the development of dashboards onboard, as well as remotely, which improve awareness of operational efficiencies among crew members and help them to conserve fuel. Where possible we continue to use ‘light’, drop-in biofuels – blends of biofuel and marine gas oil – in our vessels which reduce carbon emissions by up to 90% when using a pure biofuel blend. For further information please refer to our latest Sustainability Report.